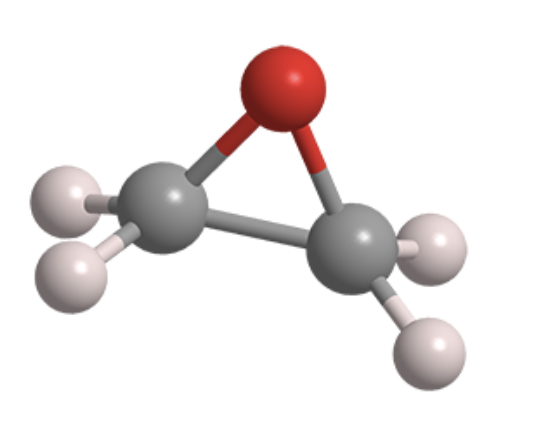

1. What Is Ethylene Oxide?

Ethylene oxide (EO) is the simplest epoxide—a three‑membered cyclic ether with formula C₂H₄O. At 25 °C its vapour pressure exceeds 100 kPa, making it a highly mobile and flammable volatile organic compound. Modern plants rely on the direct oxidation of ethylene over silver‑based catalysts promoted with chloride or rhenium to reach selectivities > 80 % (1)(2). Because EO readily alkylates DNA it is classified as a Group 1 human carcinogen by IARC (3). Regulatory bodies set very strict limits: OSHA and the EU both enforce an 8‑h TWA of 1 ppm, with a 15‑min excursion limit of 5 ppm in the United States (4). In April 2024 the U.S. EPA issued a final rule that requires chemical plants and commercial sterilizers to cut EO emissions by 90 % and implement fenceline monitoring (5).

Key downstream uses include: (a) production of monoethylene glycol (MEG) for PET and antifreeze; (b) large‑scale manufacture of ethoxylates; (c) low‑temperature sterilisation of heat‑sensitive medical devices (6); and (d) synthesis of ethanolamines and polyether polyols for the polyurethane industry.

Consequently, organisations searching how to treat EO effluent, exploring reliable solutions for ethylene oxide wastewater treatment or evaluating EO emissions control strategies will appreciate the practical insights provided here. The same applies to facilities focused on ethylene oxide sterilizer exhaust treatment.

2. Derivatives of Ethylene Oxide

EO’s ring‑opening chemistry generates a broad portfolio of intermediates vital to modern industry. Table 1 maps the principal derivative families; subsections expand on their synthesis, applications and environmental behaviour.

| Derivative Family | Main Reaction | Key Applications | Process Notes |

| Ethylene glycols (MEG/DEG/TEG) | Hydrolysis of EO | PET, antifreeze, natural‑gas dehydration | ~ 60 % of global EO demand |

| Polyethylene glycols (PEG 200–20 000 Da) | Anionic polymerisation | Lubricants, pharma excipients, inks | Biodegradable ≤ 14 kDa |

| Alcohol / acid / amine ethoxylates | Base‑catalysed ethoxylation | Surfactants for detergents & cosmetics | CSTR cascade, 120–180 °C |

| Ethanolamines (MEA / DEA / TEA) | EO + NH₃ | CO₂ capture, corrosion inhibitors | Alkaline, N‑rich effluent |

| Glycol ethers (E‑series) | EO + ROH | Paints, cleaners, printing inks | Mostly readily biodegradable |

| Polyether polyols | Sequential EO/(PO) addition | PU foams & elastomers | High‑salinity wastewater |

| Nonylphenol ethoxylates (NPEO) | EO + nonylphenol | Industrial detergents, demulsifiers | Endocrine‑disruptin g metabolite NP |

2.1 Ethylene Glycols (MEG, DEG, TEG). Controlled hydrolysis yields MEG, DEG and TEG; MEG alone consumes about 60 % of global EO. These glycols exhibit high biodegradability (BOD₅/COD ≈ 0.6) and are removed > 90 % in activated sludge (8).

2.2 Polyethylene Glycols (PEG). Anionic polymerisation produces PEGs from 200 to > 20 000 Da. Chains up to ≈ 14 kDa mineralise readily, whereas heavier grades persist longer (9). End uses range from water‑based lubricants to laxatives and ink‑jet inks.

2.3 Ethanolamines. Reacting EO with ammonia in adiabatic tubular reactors yields MEA, DEA and TEA. MEA is the workhorse solvent for amine‑based CO₂ capture; effluents are alkaline and nitrogen‑rich, thus needing advanced nitrification–denitrification (10).

2.4 Alcohol, Acid and Amine Ethoxylates. Base‑catalysed ethoxylation attaches hydrophilic EO chains to hydrophobes. Linear alcohol ethoxylates biodegrade > 99 % in WWTPs, but branched analogues and NPEO do not (11).

In practice, any engineer involved in EO derivatives treatment—for example, those treating EO surfactant wastewater or wondering how to treat ethoxylate effluent

—must balance toxicity, salinity and biodegradability. This discussion serves as a concise EtO derivative wastewater treatment guide.

3.Typical Plant Effluent Characterisation

EO and derivative plants generate three main aqueous streams (Table 2). Free EO can inhibit biomass and must be stripped prior to biological treatment (6)(12).

| Stream | Origin | Typical Range | Observations |

| Reaction water | Reaction water Absorber / scrubber condensate | COD 2 000–10 000 m g L⁻¹; pH 9–11 | EO, glycols, alcohols |

| Reactor cleaning water | Maintenance wash‑down | COD 5 000–20 000 m g L⁻¹; Salts 5–15 g L⁻¹ | KOH, acetate, catalyst fines |

| Vacuum condensate | Evaporators & vacuum systems | COD 500–2 000 mg L⁻ ¹; VOC < 50 mg L⁻¹ | Often fit for direct bio‑treatment |

Pilot SBR studies achieved 79–86 % COD removal on real EO/EG wastewater at 17 h reaction time (13). Aerobic granular sludge further boosts resiliency and settling performance (14).

These values give operators reference points when Googling typical EO wastewater characteristics, calculating the expected COD of ethylene oxide effluent or planning an overall EtO wastewater analysis campaign.

4. Effluent Treatment Strategies

4.1 Physico‑Chemical Routes

When COD is poorly biodegradable or salinity exceeds ≈ 15 g L⁻¹, physico‑chemical routes prevail:

• Evaporation–Crystallisation (ZLD). Condorchem vacuum evaporators and crystallizers combine multi‑effect evaporation with forced or falling‑film crystallisation to achieve zero liquid discharge while recovering high‑quality distillate (6)(7).

• Advanced Oxidation Processes (AOP). Fenton, ozonation or photo‑catalysis degrade recalcitrant surfactants like NPEO, reducing COD and increasing biodegradability (11)(15).

• Adsorption & Stripping. Activated carbon and steam‑air stripping remove residual EO and other VOCs before biological steps (5).

4.2 Biological Routes

For biodegradable COD < 8 g L⁻¹ and moderate salinity, biological options minimise operating costs:

• Conventional Activated Sludge (CAS). Removes > 90 % of MEG, light PEG and MEA at 12–20 h HRT (8).

• MBBR / MBR. Biofilm carriers or membranes handle loads up to 3 kg COD m⁻³ d⁻¹, producing effluent < 50 mg COD L⁻¹ (9).

• Aerobic Granular Sludge (AGS). High settleability and tolerance to shock loads; treats PEG ≤ 10 kDa (14).

• Nitrification–Denitrification / Anammox. Essential when ethanolamines raise total nitrogen above ≈ 1 g L⁻¹ (10).

4.3 Technology Selection Matrix

| Key Condition | Recommended Technology |

| COD/BOD₅ > 2 with NPEO | AOP + ZLD |

| COD < 8 g L⁻¹, TDS < 15 g L⁻¹ | CAS / MBBR + RO |

| PEG > 20 kDa, salts > 20 g L⁻¹ | UF + MEE/MVR + crystallisation |

| Organic NH₃ > 3 g L⁻¹ | Neutralisation + Fenton + biological polishing |

Altogether, choosing an EO ZLD system—whether a high‑efficiency ethylene oxide crystallizer, a customised Condorchem evaporator, or another hybrid train—depends on clear data. The matrix below helps anyone asking “how to treat EtO effluent” align treatment goals with plant constraints.

5. Conclusions

Ethylene oxide underpins numerous value chains, yet its hazards necessitate a holistic life‑cycle approach. Selecting the right mix of physico‑chemical (e.g., ZLD crystallisation) and biological technologies ensures compliance with evolving EPA and EU directives while boosting corporate ESG credentials. Publishing key performance indicators—such as > 95 % COD removal or achieving ZLD—also strengthens professional credibility and search‑engine visibility.

Ultimately, treating EO emissions effectively and selecting the best technology for ethylene oxide wastewater ensures compliance, safety and sustainability—making this piece a practical EO effluent treatment guide for decision‑makers.

References

TiO₂–Chitosan Adsorption of COD from Industrial Wastewater. Nature Scientific Reports, 2022

(turn1search6).

Shell Catalysts & Technologies. “Ethylene Oxide Catalysts – High‑Selectivity Series.” 2023.

Mitsui Chemicals selects ethylene oxide catalyst from Shell Catalysts & Technologies.

Hydrocarbon Processing, Sept 2022 (turn5search0).

IARC. “1,3‑Butadiene, Ethylene Oxide and Vinyl Halides.” Monographs Vol 97, 2008.

CDC / OSHA. 29 CFR 1910.1047 – Ethylene Oxide.

U.S. EPA. “Actions to Protect Communities and Workers from Ethylene Oxide.”

April 2024 (turn0search7).

Condorchem Envitech. “Zero‑Liquid‑Discharge (ZLD) Systems and Technologies.” 2024

(turn0search3).

Condorchem Envitech. “Industrial Vacuum Crystallizers for ZLD.” 2024 (turn0search1).

Feasibility Study on EO/EG Wastewater Treatment Using Pilot‑Scale SBR. ResearchGate,

2013 (turn1search1).

Biodegradation of real industrial wastewater containing ethylene glycol in aerobic

granular sludge. ScienceDirect, 2020 (turn1search2).

Google Patents. US 4,355,181 “Process for Preparing Ethanolamines.”

Gamma‑Radiation/H₂O₂ Treatment of Nonylphenol Ethoxylates. Journal of Hazardous

Materials, 2015 (turn1search5).

CDC Infection Control. “Ethylene Oxide Gas Sterilization.” 2023 (turn0search4).

EO Wastewater Challenges & Solutions. Enthalpy Analytical Blog, 2024 (turn0search0).

Integrated physicochemical processes for high‑COD wastewater. ScienceDirect, 2023

(turn1search0).