At WIZZUM, we specialize in industrial wastewater treatment, air pollution control, VOC emission reduction, and Zero Liquid Discharge (ZLD) solutions. Our consulting team supports industries through every phase of the process—from environmental benchmarking and FEED engineering to system implementation—ensuring both regulatory compliance and environmental excellence.

On this page, you’ll find real case studies demonstrating how our environmental consulting services help solve complex challenges in wastewater management, air emissions reduction, and sustainable resource use.

Learn more about our core environmental services to understand how we guide industries toward efficient and compliant solutions.

In 2021, an industrial site located in Portugal, specializing in the production of safety items, faced a significant environmental challenge. The facility generated wastewater with extremely high levels of contaminants, including organic loads (COD over 30,000 mg/l and BOD₅ at 2,000 mg/l), suspended solids (TSS exceeding 6,000 mg/l), and other regulated pollutants such as oils, fats, phosphorus, and nitrates. This effluent was far above permissible discharge limits, making direct release into the environment or public networks legally and environmentally unacceptable.

Additionally, there was a strategic interest in reusing treated water for irrigation, adding another layer of technical complexity to the project. Therefore, the treatment solution had to guarantee consistent water quality that met stringent discharge norms, with the potential for reuse, while maintaining compactness and operational efficiency.

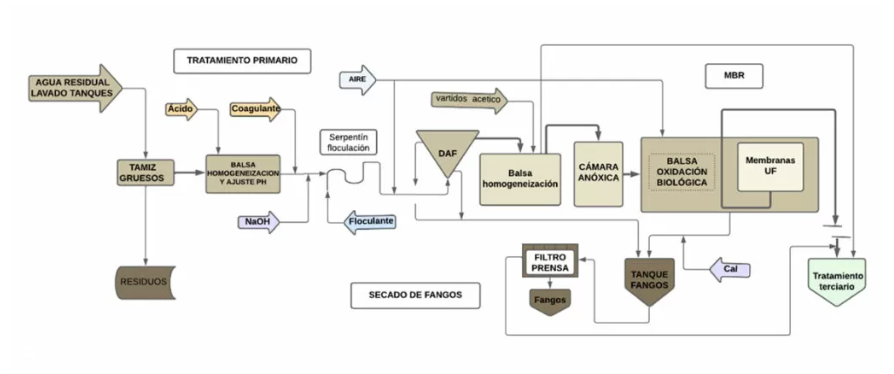

To meet these requirements, a fully integrated wastewater treatment plant was implemented. The system was designed with a daily treatment capacity of 20 m³ and a continuous flow of 1 m³/h. It combined several advanced technologies, divided into three main stages: primary, secondary, and sludge management.

In the primary phase, a high-efficiency dissolved air flotation (DAF) system was installed to remove oils, greases, and suspended solids. This flotation process, aided by chemical conditioning and flocculation, ensured excellent removal of particulate matter through the generation of microbubbles that carried contaminants to the surface.

The secondary phase consisted of a membrane bioreactor (MBR) system. This biological treatment process included an upstream anoxic chamber for nitrogen removal via nitrification-denitrification, followed by ultrafiltration membranes that guaranteed exceptional separation of solids and pathogens. The MBR ensured both a high-quality effluent and operational stability even with fluctuating loads.

Finally, a mechanical sludge treatment line, including automatic filter press systems, allowed for effective dewatering and minimization of sludge volume, reducing operational and disposal costs.

The advanced industrial wastewater treatment line successfully reduced all critical pollution indicators to levels well within discharge limits, enabling safe discharge and the possibility of water reuse for irrigation. The plant also demonstrated high reliability and low maintenance demands, thanks to the modular and compact design of the equipment used.

The project stands as a successful example of how modern water treatment technologies can be applied in high-load industrial settings to achieve regulatory compliance and environmental sustainability. It demonstrates the potential of tailored engineering in supporting industrial activity while protecting natural resources.

In 2020, a major industrial plant located in Mexico, engaged in the production of household, hygiene, and health-related consumer goods, faced a pressing environmental challenge. The facility generated considerable volumes of wastewater with high organic and chemical loads. Key pollutants included elevated levels of biological and chemical oxygen demand (BOD₅ and COD), ammoniacal nitrogen, surfactants (SAAM), and oils and fats—many of which far exceeded local regulatory discharge limits.

Moreover, pH levels fluctuated drastically, with some measurements reaching as high as 11 and as low as 0, presenting a serious risk to downstream water bodies. The company also expressed interest in reclaiming part of the treated water for reuse, which placed additional pressure on the treatment process to achieve both environmental compliance and high water quality standards.

To meet these challenges, a fully integrated wastewater treatment plant was commissioned. The design capacity was 235 cubic meters per day, with an average treatment rate of 8 cubic meters per hour. The solution was structured across three main stages: pretreatment, biological treatment with membrane bioreactor (MBR) technology, and tertiary polishing processes.

The pretreatment phase included chemical and physical homogenization of acid and alkaline effluents to stabilize pH and prepare the flow for biological treatment. This was followed by a high-capacity biological system based on MBR technology. The membrane bioreactor combined aerobic biological digestion with submerged ultrafiltration membranes, which allowed for the effective separation of solids and the degradation of organic pollutants with high efficiency.

Air diffusers and advanced recirculation systems ensured proper oxygenation and biomass activity, enabling robust nitrogen removal through nitrification and denitrification. The compact membrane modules, equipped with periodic chemical cleaning, ensured stable long-term performance and consistent effluent quality.

A final tertiary treatment step used filtration through activated carbon and flint media to further polish the effluent, enhancing its quality and odor profile to make it suitable for potential reuse. Sludge generated during the process was thickened and dehydrated through a lime dosing system and low-pressure filter press, significantly reducing waste volume and simplifying handling.

The project achieved a dramatic reduction in all key pollutants, meeting and even exceeding the standards required by Mexican environmental regulations. Treated effluent exhibited consistently low levels of BOD, COD, suspended solids, and surfactants, with stabilized pH and minimized odor—opening the possibility for safe water reuse applications.

From an environmental standpoint, the installation represented a major step forward in responsible industrial wastewater treatment and water management. The plant not only ensured regulatory compliance but also minimized its ecological footprint and prepared the facility for future operational expansion with scalable treatment technology.

This case demonstrates how thoughtful engineering and advanced biological treatment processes can resolve complex wastewater challenges in demanding industrial environments, ensuring both legal compliance and a commitment to sustainable water stewardship.

In 2009, a major food processing facility located in Valencia, Spain, faced the challenge of sustainably managing high-salinity wastewater generated from its resin regeneration processes. The effluents were characterized by elevated total dissolved solids (TDS reaching up to 60,000 ppm), high chemical oxygen demand (COD up to 31,000 ppm), and variable pH values between 5.5 and 9.5. Due to the environmental impact and regulatory constraints associated with brine disposal, the company required a solution that would not only treat the effluent effectively but also aim for zero liquid discharge (ZLD), aligning with modern sustainability standards.

To meet this objective, a tailored treatment system was installed, structured around a three-stage process that prioritizes water recovery, energy efficiency, and residue minimization.

The first step involved pH adjustment of the raw brine to optimize the treatment conditions. This was followed by a vacuum evaporation stage using a two-effect evaporator with a treatment capacity of 55,000 liters per day. The evaporation system was thermally powered by residual heat, recovered via a heat exchanger connected to a combined heat and power (CHP) plant stack. This energy integration significantly reduced operational energy costs and enhanced the overall sustainability of the system.

In the third stage, the clean distillate water was directed to the existing biological treatment facility within the plant, while the concentrated brine was further processed. Oversaturated brine was treated in a spray drying unit, and salt residues were mixed with organic biomass (bagasse) for appropriate waste handling or reuse.

This circular approach not only minimized the volume of liquid waste requiring disposal but also enabled the internal reuse of water and recovery of energy from waste streams—ensuring maximum efficiency in both environmental and operational terms.

The implemented solution led to a remarkable reduction in pollutant concentrations, with the distilled water achieving TDS values below 100 ppm and COD levels dropping to around 1,700 ppm—an outcome suitable for further biological treatment. The system maintained stable performance under demanding load conditions and proved to be highly energy-efficient due to heat recovery from industrial by-products.

This case exemplifies how industrial symbiosis and intelligent engineering can transform high-load wastewater into a manageable stream, advancing towards Zero Liquid Discharge (ZLD) solutions. It provides a replicable model for other food industry operations seeking to align with environmental stewardship without compromising industrial productivity.

In 2008, a major chemical and cosmetics manufacturer operating in Spain faced increasingly strict environmental regulations concerning industrial wastewater discharge, particularly relating to conductivity and salt content. The existing on-site biological treatment plant was no longer sufficient to comply with new municipal wastewater requirements, which mandated effluent conductivity below 3,000 µS/cm.

However, the facility’s saline wastewater—generated from production processes—exceeded 7,000 µS/cm, containing high concentrations of chlorides, sulphates, and suspended solids. Addressing this issue was especially critical in the context of water scarcity in the region, highlighting the strategic value of wastewater reuse and the need for advanced desalination and salt reduction technologies.

To ensure regulatory compliance and support sustainable operations, the facility implemented a Zero Liquid Discharge (ZLD) system designed to treat 66 cubic meters of saline wastewater per day. The solution included a combination of vacuum evaporation and brine crystallization technologies tailored for industrial wastewater treatment in high-salinity environments.

The process began with neutralization and filtration of the collected effluent to remove suspended solids. The pretreated water was then fed into a mechanical vapor recompression (MVR) evaporator, which concentrated the effluent up to 14 times. The distillate—representing the bulk of the water content—was recovered with very low residual conductivity (20–50 µS/cm) and reused in the factory or safely discharged, depending on operational needs, supporting both water reuse and resource efficiency.

The concentrated brine from the evaporator was then directed to a dedicated crystallizer, which operated at elevated temperatures to extract dissolved salts in solid form. This process produced a manageable volume of wet sludge, minimizing disposal costs and reducing environmental impact. The equipment materials were specifically selected for their high corrosion resistance, using advanced stainless steel alloys to ensure long-term durability in contact with aggressive saline solutions.

The ZLD system enabled the facility to achieve full compliance with local discharge standards, reducing effluent conductivity from over 7,000 µS/cm to under 50 µS/cm in the recovered water. Chloride levels were drastically lowered, from 3,000 mg/l to below 5 mg/l. The treated water was consistently suitable for reuse, significantly decreasing the facility’s freshwater dependency—a critical advantage in the water-scarce region of Murcia.

This is a clear example of how Zero Liquid Discharge (ZLD) solutions can support regulatory compliance, water reuse, and resource resilience in chemical manufacturing. Additionally, the installation allowed the plant to eliminate liquid discharge entirely, aligning its operations with modern environmental best practices. The solution proved not only technically effective but also economically viable, with low operating costs supported by high energy efficiency and optimized chemical usage. The success of the installation has since been recognized with several environmental awards, positioning the site as a model of sustainable chemical manufacturing.

In 2019, a pharmaceutical production facility in Spain with an international presence faced a serious environmental challenge. The site, dedicated to the manufacture of active pharmaceutical ingredients (APIs), was generating highly contaminated process emissions during its synthesis operations. The emissions contained extremely high levels of volatile organic compounds (VOCs)—reaching concentrations of up to 210 grams per cubic meter—with an airflow rate of 320 Nm³/h.

A particularly hazardous air pollutant present in the emissions was methylene chloride, a chlorinated solvent known for its significant health and environmental risks. The complexity of the site’s operations—where multiple chemical synthesis processes occurred simultaneously in a single plant—further complicated the situation. Additionally, increasingly stringent environmental regulations required a substantial VOC emissions reduction to ensure both regulatory compliance and operational safety.

To meet these requirements, an advanced air purification system was designed and installed, combining Regenerative Thermal Oxidation (RTO) technology with a quench and a scrubber. The RTO system oxidizes contaminated gases at high temperatures (1,000–1,100°C), ensuring a residence time of at least one second to guarantee the destruction of 99.9% of VOCs.

Due to the high concentration of pollutants, the system included a dilution stage where 15,000 Nm³/h of fresh air was mixed with the process stream. This ensured safe operation and maintained self-sustaining combustion conditions (autothermicity). The quench and scrubber components were incorporated downstream of the RTO unit to remove acidic gases, such as hydrogen chloride, generated during the combustion of halogenated compounds.

This multi-stage solution was specifically tailored for industrial settings with high contaminant loads, offering both reliability and efficiency while remaining compliant with occupational health and safety standards.

The system achieved outstanding results, eliminating 99.9% of airborne pollutants and maintaining emissions well below regulatory thresholds. The final emission values after treatment were:

VOCs and halogenated compounds: ≤ 20 mg/m³

Carbon monoxide (CO): ≤ 100 mg/m³

Nitrogen oxides (NOx): ≤ 150 mg/m³

Hydrogen chloride (HCl): ≤ 23 mg/m³

The system guaranteed a thermal efficiency of at least 97% and a functional performance of 99% during continuous operation.

Beyond regulatory compliance, the installation transformed the plant into a safer, more environmentally responsible workplace. It set a benchmark in the pharmaceutical sector for emission control technologies and reinforced the company’s commitment to sustainable and health-conscious industrial practices.

In 2017, a large plastic packaging production plant faced a pressing environmental challenge. Situated in a densely populated urban area, the factory needed to significantly reduce its volatile organic compound (VOC) emissions resulting from rotogravure printing and lamination processes.

The plant was required to adapt to increasingly strict local air pollution regulations, particularly relevant to industrial facilities in urban environments, where environmental compliance and public health concerns intersect. A critical complexity lay in the operational variability: with eight printing lines and one lamination line operating in different combinations, both airflow rates and VOC concentration levels fluctuated widely—posing a challenge to any standard industrial air pollution control system.

The contaminated airflow to be treated reached an impressive 230,000 Nm³/h, with VOC concentrations generally below 1 g/Nm³ and dust levels under 0.3 mg/Nm³. The chemical composition of the emissions included ethyl acetate, ethyl alcohol, isopropanol, ethanol, and propylene glycol monomethyl ether—a complex mix requiring a high-performance VOC abatement technology tailored to large-scale industrial air treatment in the flexible packaging sector.

To meet this demanding context, a comprehensive air treatment system was implemented. The solution included:

Two prefilters with progressive filtration grades (G4 to F9),

Two parallel zeolite rotor concentrators, and

A regenerative thermal oxidizer (RTO) with a thermal recovery steam boiler.

The zeolite concentrators were used to adsorb and concentrate solvents from the large volumes of air, enabling a much smaller and more efficient RTO unit to handle the concentrated stream. Each rotor achieved a 9:1 concentration ratio and offered a 95% VOC removal efficiency.

The RTO unit, with a treatment capacity of 50,000 Nm³/h, was designed to operate at 800–850°C with a minimum one-second residence time, ensuring 99.9% destruction of VOCs. A hot bypass system was included, allowing excess heat to be diverted from the RTO directly to a steam boiler in the event of high VOC load, thus maintaining stable temperatures while generating usable energy.

The project delivered exceptional results. The air purification system reduced VOC emissions to levels well below the local legal thresholds (≤ 50 mg/m³ for VOCs and NOx), with guaranteed thermal efficiency of at least 97% and operational performance exceeding 99%. These values ensured full alignment with EU industrial emissions standards for air pollution control.

In addition to environmental compliance, the plant achieved measurable operational savings by integrating a steam energy recovery system. The boiler now generates one ton of steam per hour at 6 bar and 160°C for internal reuse—saving approximately €10,000 per month in energy costs. This approach supports both emission reduction and sustainable energy management in industrial operations.

As a result, the production facility was transformed from a pollution hotspot into a model of urban industrial sustainability. It was recognized by local environmental authorities as a benchmark for responsible manufacturing within dense metropolitan areas, reinforcing the value of combining advanced VOC abatement systems with energy-efficient technologies.

In 2021, a cosmetic packaging production facility located in Spain undertook a project to improve the environmental safety of its air emissions, with a focus on VOC emission reduction and air pollution control. The plant, involved in processes that release volatile organic compounds (VOCs) such as ethanol, ethyl acetate, acetone, and methyl acetate, needed to comply with increasingly rigorous industrial emissions regulations aimed at controlling pollutants harmful to both human health and the environment.

With a total airflow of 6,000 m³/h to be treated, the primary concern was ensuring the effective capture and neutralization of solvent vapors generated during the cosmetic packaging processes—without disrupting the continuity of industrial production or increasing operational complexity. The project required a high-efficiency VOC treatment solution that could operate reliably under variable conditions while maintaining full regulatory compliance.

To meet these objectives, a compact and reliable air pollution control system was implemented, centered on a Venturi scrubber made of high-resistance polypropylene (PP). This material choice was critical for its chemical durability and resistance to the corrosive effects of solvent-laden air.

The scrubber operates by accelerating the contaminated air stream through a narrow throat, creating high turbulence and maximizing contact between the air and a scrubbing liquid. This interaction captures and removes the VOCs from the air stream through absorption and impaction mechanisms.

The full system included:

A Venturi scrubber unit built in PP, ensuring corrosion resistance.

A centrifugal fan to maintain steady airflow across the system.

An electrical control panel to monitor and manage operational parameters.

Air ducting and piping for optimal flow distribution.

This configuration offered an efficient yet low-maintenance solution suitable for mid-scale industrial facilities with relatively stable pollutant profiles.

The implementation of the Venturi scrubber system resulted in a significant reduction of airborne VOCs within the production environment. Ethanol, ethyl acetate, acetone, and methyl acetate levels were effectively reduced to concentrations compliant with local air quality regulations and workplace exposure limits, supporting both air pollution control and occupational safety.

The system’s design provided consistent VOC abatement performance with minimal energy consumption and low maintenance requirements. Its seamless integration into the existing industrial infrastructure ensured that production continuity was fully maintained during and after installation.

Beyond regulatory compliance, the solution contributed to notable Air Quality Indoor Improvement (AQII), fostering a safer and healthier workplace for operational personnel. It also reinforced the company’s image as a sustainable manufacturer committed to environmental responsibility and clean technologies.

This case demonstrates the effectiveness of targeted scrubbing technologies in managing VOC emissions in specialized sectors such as cosmetic packaging, where solvent vapor control is critical and precise air purification systems are essential to both process integrity and environmental stewardship.

This solution aligns with the European Union’s Solvent Emissions Directive (SED), which regulates VOC emissions from industrial activities involving organic solvents to safeguard both environmental and occupational health.

In 2019, a vegetable oil production facility in Spain faced the need to control air emissions generated during key stages of its industrial process. The plant emitted a combination of volatile organic compounds (VOCs) and fine particulate matter (dust)—both subject to strict environmental and workplace safety regulations.

With a total airflow of 18,000 m³/h, the installation needed a robust and efficient system capable of treating high-volume emissions containing both gaseous and particulate pollutants. Furthermore, the system required compliance with ATEX (Atmosphères Explosibles) standards due to the potentially explosive nature of some of the process components.

To address this complex scenario, a two-stage air treatment system was designed and installed. At the heart of the solution was a double-stage Venturi BIO-scrubber, constructed entirely in stainless steel (SS) for durability and chemical resistance. This wet scrubbing stage was specifically tailored to capture and neutralize VOCs as well as coarse particles through intense gas-liquid interaction.

To ensure complete removal of residual fine dust, the BIO-scrubber was followed by a baghouse filter, which provided high-efficiency dry filtration. The baghouse effectively captured even the finest particulates, ensuring emission levels remained well within legal thresholds.

Supporting components included:

A centrifugal fan to manage airflow and maintain pressure levels.

Air piping engineered for optimal flow and minimal resistance.

An electrical control panel for automated system operation and monitoring.

The full assembly was designed and certified in accordance with ATEX requirements, ensuring safe operation in potentially explosive environments.

.

The implementation of the dual-stage air purification system successfully addressed both the gaseous (VOC) emissions and particulate matter components of the plant’s emissions. VOC emission levels and industrial dust concentrations were reduced significantly, enabling the facility to meet and surpass air pollution control regulations and environmental compliance thresholds, while also adhering to ATEX safety standards for explosive atmospheres.

The integration of wet scrubbers and dry filtration technologies ensured a comprehensive industrial air treatment solution, offering high removal efficiency across a broad spectrum of pollutants, including volatile organic compounds (VOCs) and fine particles. The system was engineered for continuous operation, with minimal maintenance and high operational reliability—even in the challenging environmental conditions typical of food industry facilities.

The project stands as a benchmark in emission control for agricultural and food processing industries, demonstrating how advanced air purification systems, combining scrubber and filter technologies, can ensure environmental protection, worker safety, and regulatory compliance, even under high airflow demand scenarios.

This approach aligns with the principles of the Industrial Emissions Directive (IED) established by the European Commission, which promotes integrated strategies for reducing industrial pollution across member states.